3 Benefits of Approval Management in Manufacturing

Friday, December 14, 2018

The goal of approval management software is to replace approval processes with workflow automation. Do you have a complex approval process? Do you require more insight into the approval process? Is your approval process effective, but slow (i.e. missing deadlines)? If you answered yes to any of these, you could likely benefit from automating your approval processes.

While mostly having a foundation in office environments, the idea of workflow began in the manufacturing sector to coordinate tasks between people. Modern businesses have adopted the term to enjoy the benefits of improved efficiency, better responsiveness, work process transparency, and increased profitability.

These benefits sure sound great on paper. But how are they applied to a manufacturing process? What sort of red tape may a company have to worry about before implementing workflow management?

For example, PPAP helps define the approval process for new parts, revised parts, or parts created from changed production methods. PPAP helps component suppliers control costs and maintain a high level of quality.

PPAP is primarily used in automotive development, however, it didn’t start there. It has roots back in the 1980s when America was looking to gain back it’s manufacturing edge with Japan. In manufacturing, you’ll deal with varying levels of customer design specifications. Implementing a PPAP process will ensure that live production runs will be able to meet varying levels of requirements.

The PPAP process can be complex, which is why it’s accomplished by 18 elements. (To read a breakdown of each element, check out a great write up from Automotive Engineering HQ here)

This type of approval process is typically reserved for larger automotive manufacturers and companies involved in various aerospace industries. The PPAP process is a very drawn out and involved occurrence but lets engineers ensure that all areas of the design and production processes have been reviewed thoroughly to ensure that only high-quality product will be allowed to ship to the end customer.

In similar breaths, the FAA’s PMA and the FDA’s CGMP will provide a complex, but effective method of approval management for manufacturers.

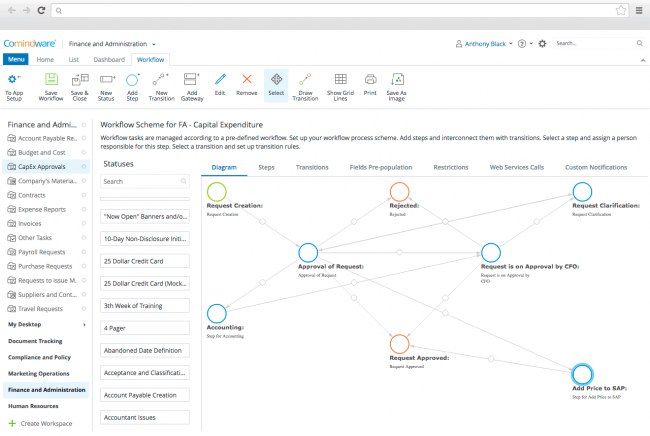

Model your own workflows right from web-browser. Give Comindware Tracker a try Many manufacturing companies may already have an ERP or MRP solution in place and look to reap the benefits of workflow management and tracking approvals. In fact, some of the key features of MES software include change management, document management, expedited jobs, and order prioritization; all of which can surely help improve your overall workflow.

Model your own workflows right from web-browser. Give Comindware Tracker a try Many manufacturing companies may already have an ERP or MRP solution in place and look to reap the benefits of workflow management and tracking approvals. In fact, some of the key features of MES software include change management, document management, expedited jobs, and order prioritization; all of which can surely help improve your overall workflow.

However, many situations can occur that will require you to have a separate solution to handle your approval management and overall workflow process. Doing so will provide many great benefits for your organization.

The main way approval management will help reduce your organizational costs is by better control of procurement. Approval management can (or rather should) exist throughout the purchasing process for your manufacturing plant. If an employee needs a certain part to complete an order, he can put in the request. This request gets passed to management to verify the need, ensure the accurate part is ordered, purchased and delivered in a timely manner.

Having an improved cost control via authorizations and approvals will ensure the necessity and accuracy of individual purchases. In turn, this will reduce supply costs through improved capabilities to compare vendor options. It will also reduce the administrative labor costs associated with purchasing activities through the use of software automation.

From a non-financial standpoint, quality control helps reduce risk by providing safe products to your customers as well as an overall safe manufacturing process. This ensures your manufacturing equipment can be utilized to it’s fullest lifespan, and your workers aren’t bogged down with errors, repairs, or other time-consuming tasks.

Approval management adds in another level of checks and balances to your quality control process, which in turn improves your quality control. As mentioned above, regulatory compliance is an issue in manufacturing, and approval management will help you stay on track. Compliance can be required for permitting, can be an eligibility condition for bid-consideration, or a necessity to avoid financial penalties or other legal action.

Some positions may be permitted to create new purchase orders. These orders will then be sent to a manager before they are officially ordered. Some could make the argument that allowing the first point of contact (the person submitting the request) to simply place the order would, in fact, speed up the process. However, orders should be left to a proper approval process to

Approval management can also be found in approving manufacturing orders. Approved orders can be added to the production schedule for workers to see and report on operations. They can also be scheduled efficiently to ensure the best use of machine uptime and that orders are being produced alongside other orders in the quickest manner possible.

Some products may be better manufactured close to demand to shorten supply chains and provide quick response to demand changes. Optimizing the scheduling will become critical to squeezing out more production from your floor. Rather than letting any employee add an order to the schedule, letting an appropriate management personnel optimize the schedule via an approval process would benefit the company as a whole.

While mostly having a foundation in office environments, the idea of workflow began in the manufacturing sector to coordinate tasks between people. Modern businesses have adopted the term to enjoy the benefits of improved efficiency, better responsiveness, work process transparency, and increased profitability.

These benefits sure sound great on paper. But how are they applied to a manufacturing process? What sort of red tape may a company have to worry about before implementing workflow management?

Table of Contents

Regulation is all around us

The automotive industry deals with the production part approval process or PPAP. The aviation agency deals with the FAA Parts Manufacturer Approval (PMA) process, and the pharmaceutical industry deals with Current Good Manufacturing Practices (CGMPs) advised by the FDA. While only a small glimpse at the vast amount of manufacturing industries that exist, it goes to show just how involved and regulated manufacturing approval management can really be.For example, PPAP helps define the approval process for new parts, revised parts, or parts created from changed production methods. PPAP helps component suppliers control costs and maintain a high level of quality.

PPAP is primarily used in automotive development, however, it didn’t start there. It has roots back in the 1980s when America was looking to gain back it’s manufacturing edge with Japan. In manufacturing, you’ll deal with varying levels of customer design specifications. Implementing a PPAP process will ensure that live production runs will be able to meet varying levels of requirements.

The PPAP process can be complex, which is why it’s accomplished by 18 elements. (To read a breakdown of each element, check out a great write up from Automotive Engineering HQ here)

This type of approval process is typically reserved for larger automotive manufacturers and companies involved in various aerospace industries. The PPAP process is a very drawn out and involved occurrence but lets engineers ensure that all areas of the design and production processes have been reviewed thoroughly to ensure that only high-quality product will be allowed to ship to the end customer.

In similar breaths, the FAA’s PMA and the FDA’s CGMP will provide a complex, but effective method of approval management for manufacturers.

Simplify the Process

Can the approval management process be simplified? Many approval management software options will provide benefits to better your overall workflow. Companies who are looking to step away from a simple spreadsheet or email based activity tracking process will likely benefit the most from workflow management software. Key capabilities for tracking documents, assigning tasks, and monitoring data will be optimal for better organizing your business processes. For example, through high-quality workflow modeling, you can help your team deliver products and services more consistently and reliably while complying with any regulations. Model your own workflows right from web-browser. Give Comindware Tracker a try Many manufacturing companies may already have an ERP or MRP solution in place and look to reap the benefits of workflow management and tracking approvals. In fact, some of the key features of MES software include change management, document management, expedited jobs, and order prioritization; all of which can surely help improve your overall workflow.

Model your own workflows right from web-browser. Give Comindware Tracker a try Many manufacturing companies may already have an ERP or MRP solution in place and look to reap the benefits of workflow management and tracking approvals. In fact, some of the key features of MES software include change management, document management, expedited jobs, and order prioritization; all of which can surely help improve your overall workflow. However, many situations can occur that will require you to have a separate solution to handle your approval management and overall workflow process. Doing so will provide many great benefits for your organization.

Benefits

Reduce Costs

Manufacturers are always looking to stay ahead of the aggressive competition that can exist locally and worldwide. To avoid losing out to overseas manufacturers, one might look to reduce costs via better quality management by implementing an approval management process.The main way approval management will help reduce your organizational costs is by better control of procurement. Approval management can (or rather should) exist throughout the purchasing process for your manufacturing plant. If an employee needs a certain part to complete an order, he can put in the request. This request gets passed to management to verify the need, ensure the accurate part is ordered, purchased and delivered in a timely manner.

Having an improved cost control via authorizations and approvals will ensure the necessity and accuracy of individual purchases. In turn, this will reduce supply costs through improved capabilities to compare vendor options. It will also reduce the administrative labor costs associated with purchasing activities through the use of software automation.

Quality Control

The goal of quality control is to provide your customers with a fantastic product and avoid defects & risk. In turn, this provides you with a cycle of business. Quality products will turn into customer loyalty, which becomes repeat business, and can lead to new business via customer referrals. In other words, quality products will indirectly lead to more business and sales.From a non-financial standpoint, quality control helps reduce risk by providing safe products to your customers as well as an overall safe manufacturing process. This ensures your manufacturing equipment can be utilized to it’s fullest lifespan, and your workers aren’t bogged down with errors, repairs, or other time-consuming tasks.

Approval management adds in another level of checks and balances to your quality control process, which in turn improves your quality control. As mentioned above, regulatory compliance is an issue in manufacturing, and approval management will help you stay on track. Compliance can be required for permitting, can be an eligibility condition for bid-consideration, or a necessity to avoid financial penalties or other legal action.

Optimize order times

Approval management can be more commonly found in purchasing. In relation to manufacturing, that usually refers to purchase orders for necessary parts and supplies to complete the manufacturing orders.Some positions may be permitted to create new purchase orders. These orders will then be sent to a manager before they are officially ordered. Some could make the argument that allowing the first point of contact (the person submitting the request) to simply place the order would, in fact, speed up the process. However, orders should be left to a proper approval process to

- Ensure the need exists

- Ensure the proper quantity is ordered

- Ensure the price fits into the budget

Approval management can also be found in approving manufacturing orders. Approved orders can be added to the production schedule for workers to see and report on operations. They can also be scheduled efficiently to ensure the best use of machine uptime and that orders are being produced alongside other orders in the quickest manner possible.

Some products may be better manufactured close to demand to shorten supply chains and provide quick response to demand changes. Optimizing the scheduling will become critical to squeezing out more production from your floor. Rather than letting any employee add an order to the schedule, letting an appropriate management personnel optimize the schedule via an approval process would benefit the company as a whole.

Posted on: in Tips and Tricks